Produkter

TensoBar

TensoBar PRO

Glass Fiber Reinforced Polymer (GFRP) Reinforcement

Reinforcement made of glass fiber reinforced polymer, abbreviated as GFRP, is a lightweight and high-performance solution that offers strength, durability, and cost-effectiveness compared to conventional steel reinforcement. TensoBar is developed for the most demanding construction projects, providing high mechanical stability and corrosion resistance.

Product Data

Advantages

Economy and Environment

By replacing conventional metal reinforcement with TensoBar, you can reduce your total costs by up to 50%. Lower weight, simpler handling, and a 100-year service life.

Strength & Reliability

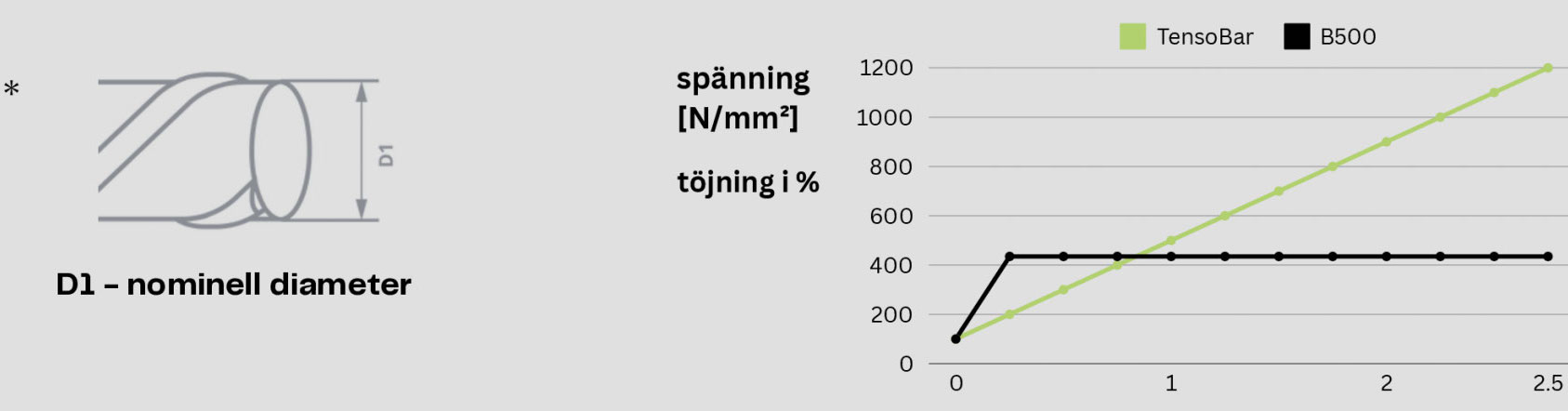

TensoBar’s tensile strength is three times higher than that of traditional metal reinforcement bars. TensoBar does not conduct electricity, does not cause radio interference, and is non-magnetic. It exhibits high chemical and corrosion resistance, with a technical service life of 100 years. Better for the environment now and sustainably over time.

Transportation & Installation

Supplied in 50-meter rolls and featuring low weight, TensoBar is easier to handle during transport, in storage, and on-site, leading to lower costs for labor, shipping, and warehousing.

Durability and Service Life

TensoBar has high corrosion resistance, significantly extending the lifespan of concrete structures. We believe a 100-year perspective on new construction is the only way forward for the sake of the environment. With this in mind, we minimize material waste and energy losses over time—ensuring a truly sustainable construction.

TensoBar PRO reinforcement is manufactured in our factory in Latvia. The factory is designed to leave as little impact on the environment as possible. Through smart, energy-efficient processes, we do what we can to reduce carbon emissions.

CO₂-neutral footprint by using renewable energy in the manufacturing process. Sustainable and innovative, positioning us as a leading choice for the environmentally conscious who cherishes responsible designs.

Comparison with Metal Reinforcement B500

|

Metal Rebar |

||

| Nominal diameter* | Tensile Force | Nominal diameter* | Tensile Force |

| 6mm | 36kN | 9mm | 32kN |

| 8mm | 60kN | 12mm | 56kN |

| 10mm | 93kN | 14mm | 77kN |

| 12mm | 141kN | 18mm | 127kN |

TensoBar reinforcement is suitable for a wide range of construction projects such as floors, foundations, roads, sidewalks, and support structures.

The Factory

At our 2,000 m² facility in Latvia, backed by 15 years of experience, we manufacture TensoBar and glass-fiber-reinforced composite mesh and reinforcement.

We are CE-marked and certified according to EAD 260023-00-0301—the first European standard for GFRP reinforcement. Our production process, powered by solar energy and using high-quality European materials, ensures minimal environmental impact. Because GFRP reinforcement is so lightweight, it is much easier to handle on worksites, in warehouses, and during transport—significantly reducing the overall carbon footprint throughout its lifecycle.

Our strength lies in our independence from external disruptions, maintained by exclusively using European materials from reliable partners. Combined with our eco-friendly, solar-powered operations, our facility delivers an annual production capacity of 6,500,000 meters of composite reinforcement bars, guaranteeing a reliable supply for a variety of construction needs.

TensoBar sets new standards for building driveways, patios, sidewalks, industrial floors, parking lots, and many other concrete features in our surroundings.

TensoBar PRO

Reinforcement on rolls with our standard length of 50 m

- Diameters: 6, 8, 10, and 12 mm

- Standard Roll Length: 50 m

Pre-Cut Lengths

We can cut the reinforcement into lengths of 1–12 m. Pricing is provided upon request.

- Standard Reinforcement Length: 1–12 m (Other lengths available upon request)

- Reinforcement Bars per Pallet: up to 500 pcs

Specific Requirements?

With a pre-order, we can produce various diameters and lengths of reinforcement. Please contact us for more information.