EPSCement®

Areas of use

EPSCement® can be used for all types of floor constructions, where surfaces need to be filled up to complete floors. After coating with leveling/sanding kit, EPSCement® provides floor surfaces strong enough to be covered with carpet, tiles, parquet, etc.

Other areas of use are e.g., flat on ground, parking deck, heat-insulating outer roof with fall construction and wall plaster indoors/outdoors, patio, garden path, attic, pool, floating jetty, garage driveway, repair of water damage, etc.

Overview Villa

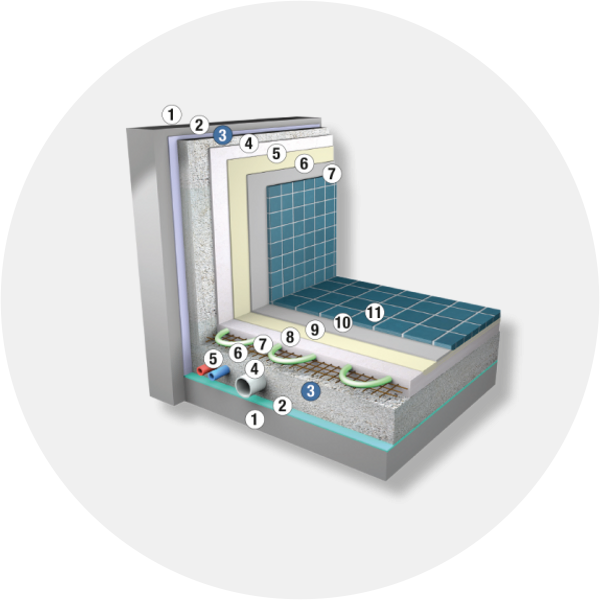

Sound-absorbing bathrooms for a higher standard of living

EPSCement® is advantageously used for casting bathroom floors. EPSCement® adds less weight and creates a solid moisture-proof floor construction especially suitable for waterproofing systems with ceramic tiles.

The drying time is short, and no moisture is added to the building thanks to the self-drying properties. EPSCement® contains no organic material and thus cannot mold. With concrete and insulation in the same material, there will be much less energy loss. EPSCement® can be both cast on the floor and sprayed on the wall.

BATHROOM FLOOR ON CONCRETE

WALL: 1. Existing concrete/stone wall, 2. Primer, 3. EPSCement®, 4. Wall plaster, 5. Sealing layer, 6. Adhesive, 7. Tile

FLOOR: 1. Concrete, 2. Plastic foil*/primer, not age-resistant, 3. EPSCement®, 4. Sewage pipes, 5. Hot and cold-water pipes, 6. Rebar, 7. Underfloor heating embedded in floating filler, 8. Floating filler, 9. Sealing layer, 10. Adhesive, 11. Tile

*Plastic foil, not age-resistant - Only if you want a floating construction.

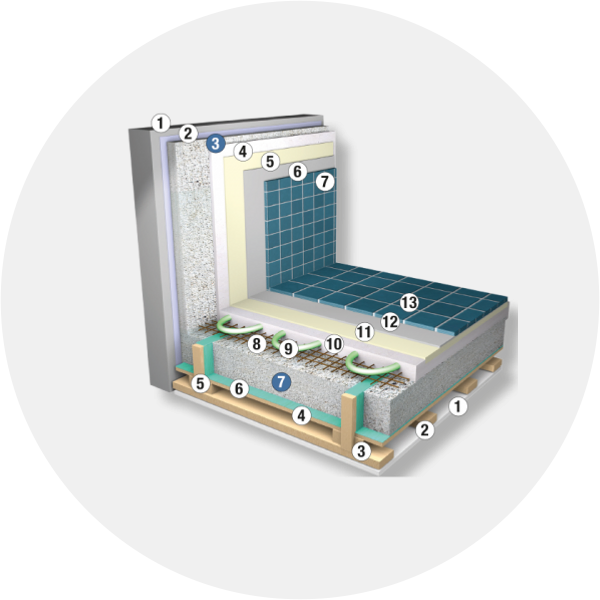

WALL AND BATHROOM FLOOR ON WOODEN JOIST

WALL: 1. Existing concrete/stone wall, 2. Primer, 3. EPSCement®, 4. Wall plaster, 5. Sealing layer, 6. Adhesive, 7. Tile

FLOOR: 1. Suspended ceiling, 2. Furring, 3. Ruler, 4. Ventilated foundation, 5. Wooden joists 45 x 220 mm, 6. Plastic foil*, 7. EPSCement®, 8. Rebar, 9. Underfloor heating embedded in floating filler, 10. Floating filler, 11. Sealing layer, 12. Adhesive, 13. Tile

*Plastic foil, not age-resistant - We only need the plastic to ensure that all water droplets remain when laying, for the quick curing process.

Insulating floor on ground with EPSCement® (e.g., basement floor)

When casting a new concrete floor or replacing an old one, it is advantageous to cast with EPSCement®. Because EPSCement® is easy to diffuse and can breathe, the construction can take care of any additional moisture.

The drying time is short, and no moisture is added to the building thanks to the self-drying properties. EPSCement® contains no organic material and thus cannot mold. With concrete and insulation in the same material, there will be much less energy loss. If you then cover EPSCement® with underfloor heating, you only heat the filler layer and not the entire slab as with ordinary concrete.

RENOVATION FLOOR ON GROUND

1. Macadam - capillary barrier layer, 2. Ground cloth, 3. EPSCement®, 4. Sewage pipes, 5. Hot and cold-water pipes, 6. Rebar, 7. Underfloor heating embedded in floating filler, 8. Floating filler at least 20mm

Insulating & sound-absorbing floor on concrete slab

The drying time is short, and no moisture is added to the building thanks to the self-drying properties. EPSCement® contains no organic material and thus cannot mold.

With concrete and insulation in the same material, there will be much less energy loss. If you then cover EPSCement® with underfloor heating, you only heat the filler layer and not the entire slab as with ordinary concrete.

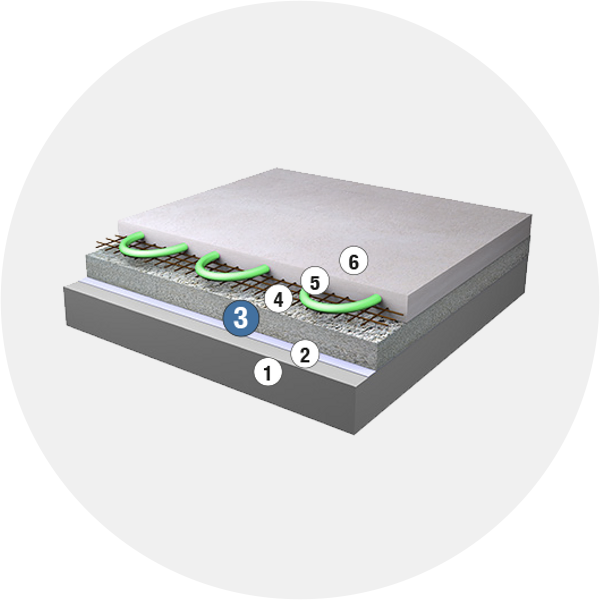

FLOOR ON CONCRETE SLAB

1. Concrete slab, 2. Plastic foil*/Primer, 3. EPSCement®, 4. Rebar, 5. Underfloor heating, 6. Filler

*Plastic foil, not age-resistant - Only if you want a floating construction.

Insulating & sound-absorbing floor on wooden joists

With EPSCement® in wooden joists, you create safe floors with stability similar to a concrete floor but with low weight and without delaying drying times and with minimized risk of water damage.

Here you also save building height as EPSCement® is added to the upper edge of the rule and then filler, no "plus heights".

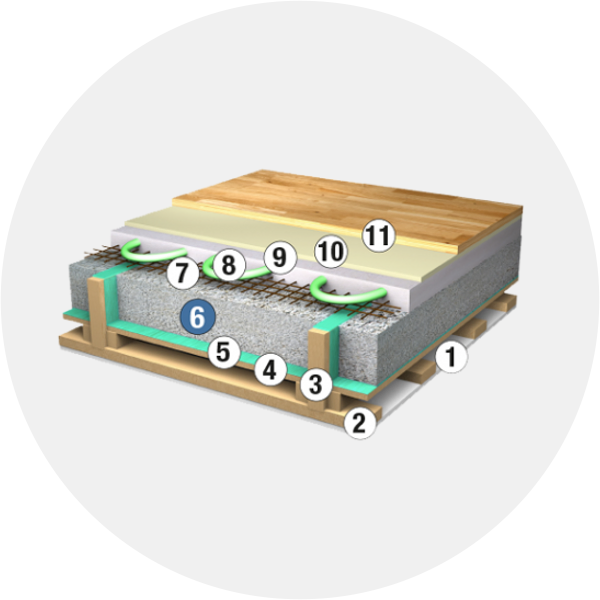

FLOOR ON WOODEN JOISTS

1. Suspended ceiling, 2. Furring, 3. Ruler, 4. Rope bottom, 5. Plastic foil, not age-resistant, 6. EPSCement®, 7. Rebar, 8. Underfloor heating, 9. Floating filler, 10. Sealing layer, 11. Parquet

Floors on concrete joists with embedded installations

In the case of existing joists that are to be poured into different installations - Pour on with the thickness needed but min. 30mm EPSCement® and min. 15mm filler.

With EPSCement®, you get a step sound dampening layer for underlying surfaces.

FLOOR ON CONCRETE JOISTS

1. Concrete floor, 2. Plastic - not age-resistant, 3. EPSCement®, 4. Ventilation embedded, 5. Drainage cast in, 6. Hot and cold-water pipes, 7. Electricity embedded, 8. Fiber cable embedded, 9. Rebar, 10. Underfloor heating, 11. Filler

EPSCement® for ceiling joists

Here, the construction is similar in design to wooden joists, but can also be cast on structural sheet metal. This construction can be used when you want to build on a garage/extension to a nice outdoor room or extend the home.

As the material has fire class A2, which is non-combustible, it also provides fire protection.

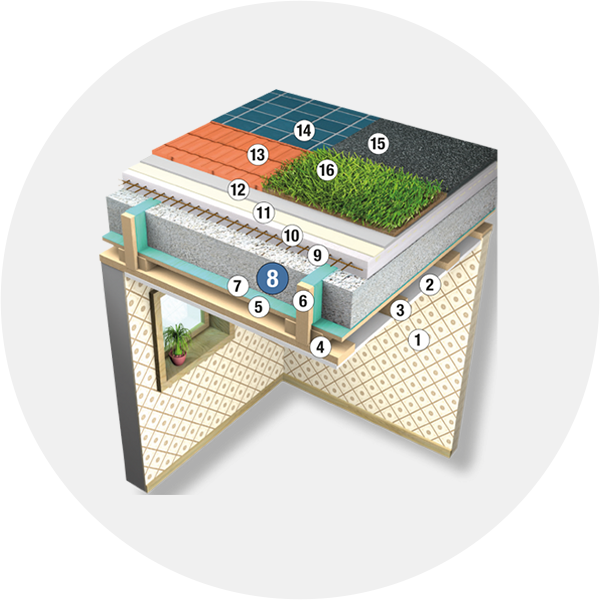

EPSCEMENT® AT CEILING JOISTS

1. Wall, 2. Suspended ceiling, 3. Sparse panel, 4. Ruler, 5. Rope base, 6. Wooden joist 45 x 220 mm, 7. Plastic foil*, 8. EPSCement®, 9. Rebar, 10. Floating filler, 11. Sealing layer, 12. Possible adhesive depending on the surface layer, 13. Tiles, 14. Roof tiles, 15. Asphalt/roofing felt, 16. Grass roof

*Plastic foil, not age-resistant - We only need the plastic to ensure that all water droplets remain when laying, for the quick curing process.

Insulating foundation / slab

Fast and insulating foundations without energy-sucking cold bridges. With this solution, you avoid long waiting times for the casting to be coated.

Already after 12 hours, reinforcement / rebar and filler can be laid. Cover the floor according to the screed manufacturer's recommendation.

BASIC

1. Macadam - capillary breaking layer, 2. Ground cloth, 3. Edge element, 4. EPSCement®, 5. Rebar, 6. Underfloor heating embedded in floating filler, 7. Floating filler at least 20mm

Insulating yard joists

Less weight on existing construction and better insulation. Can be reviewed after 12 hours.

With the insulation that is built into the material, you can lay a heating coil to combat the risk of slipping in winter and that it thaws when the spring sun comes out.